EXPLOSION PROTECTION TERMINOLOGY: WHAT ARE Pred & Pes?

In explosion protection of enclosures, Pred and Pes are two terms that often are used interchangeably, but are not the same thing. Pred, or “reduced pressure,” is the maximum pressure developed within an enclosure during a vented deflagration. Pes is the enclosure strength. Pes is defined as 2/3 of the enclosure’s ultimate strength if deformation of the enclosure can be tolerated or 2/3 of the enclosure’s yield strength if deformation cannot be tolerated.

When calculating the required vent area for an enclosure, NFPA standards state that Pred cannot exceed Pes (as defined above). When performing our calculations, we set Pred equal to Pes in order to minimize our vent size, and that leads to confusion of the terms. Also, many enclosure manufacturers will state a “Pred” for the enclosure, when they really should refer to Pes, or an “allowable” Pred. Pes must be provided for explosion protection design.

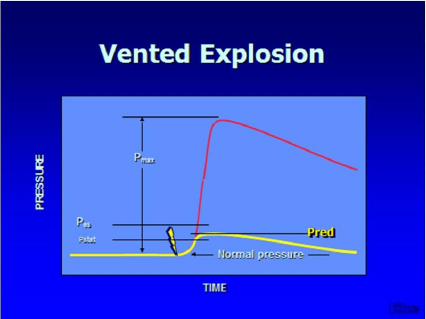

Pred vs. Pes is illustrated below, with Pstat being the explosion vent’s burst pressure, and Pmax being the max pressure of the burning dust in a vessel as determined by the ASTM E1226 dust test. If we can keep Pred below Pes, the enclosure won’t explode. Please note: During a suppressed deflagration, “Total Suppressed Pressure” replaces Pred in the illustration, but the idea is identical. Keep TSP below Pes and the enclosure won’t explode.